why us

We build long-lasting and healthy relationships. We are committed to delivering high-quality products and assisting in packaging selection. We print on certified and tested cardboard using top-quality inks. We don’t settle for half-measures. Our cardboard is meant to stand out and translate into effective sales. The printing press is a crucial link in the entire product sales chain, so we place great emphasis on adhering to previously agreed deadlines. A well-stocked cardboard warehouse and reliable suppliers enable us to significantly shorten the lead time for your orders. Our Customer Service Department is always ready to assist. We’ll advise and answer all your questions.

PUNCTUALITY

TRUST

QUALITY

How we work

During meetings, we familiarize ourselves with the product and project requirements,

We seek the most advantageous solutions and present production possibilities,

We provide a price quote and lead time,

In the design studio, we create a Mockup on the final cardboard to check the product fit,

We send die-cut outlines for graphic alignment,

We verify the project correctness and prepare files for further processing,

Before final production, we can perform a print trial,

Depending on the previously agreed assumptions, we carry out individual production stages,

The Quality Department continuously monitors the correctness of each process,

Lead time is determined individually, but on average, we assume 7-14 days for order fulfillment,

Assembled cardboard boxes are delivered in bulk cardboard boxes,

Finished packaging is shipped on pallets wrapped in stretch film, secured with corner protectors,

Each bulk cardboard box and pallet is properly labeled for quick identification,

We handle delivery using our own or external transport.

The Quality Department continuously monitors the production process,

99% of production is done on-site, protecting project privacy,

We react immediately in case of issues,

The Customer Service Department is always available for advice and assistance.

Our Values

The foundation of relationship building. Packaging production is a process we aim to explain and demonstrate in the simplest way possible. In the long term, we save time and costs during subsequent project executions. We’ll address difficult questions and translate expectations into production possibilities.

Our clients appreciate our printing press for adhering to previously agreed deadlines. Packaging production is just part of the sales chain, so we don’t allow delays that could affect subsequent processes or generate additional costs

For recurring productions, we offer favorable or fixed prices. We also propose storing finished packaging awaiting your later call-off. By determining annual demand, we can divide shipments and payments into stages

We use certified and tested materials. We print on cardboard that doesn’t tend to crack or delaminate. Print quality and finishes are important to us, as is the repeatability of orders. The Quality Department continuously monitors each production stage and eliminates any inconsistencies.

Communication, punctuality, flexibility, and quality influence the trust we uphold. We aim for the sales success of your product and future projects. We don’t settle for half-measures, which is why clearly defined values allow us to further develop

Many opportunities

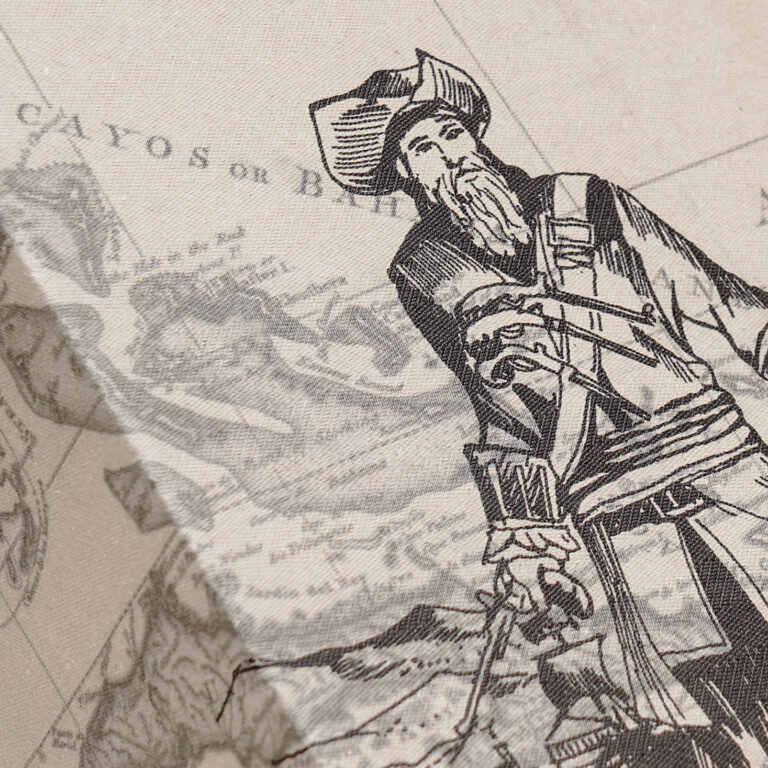

Printing

We print on offset machines up to B1 sheets. Paper weight 130g to 480g.

Die-Cutting

We cut materials with low grammage, solid cardboard, and plastics.

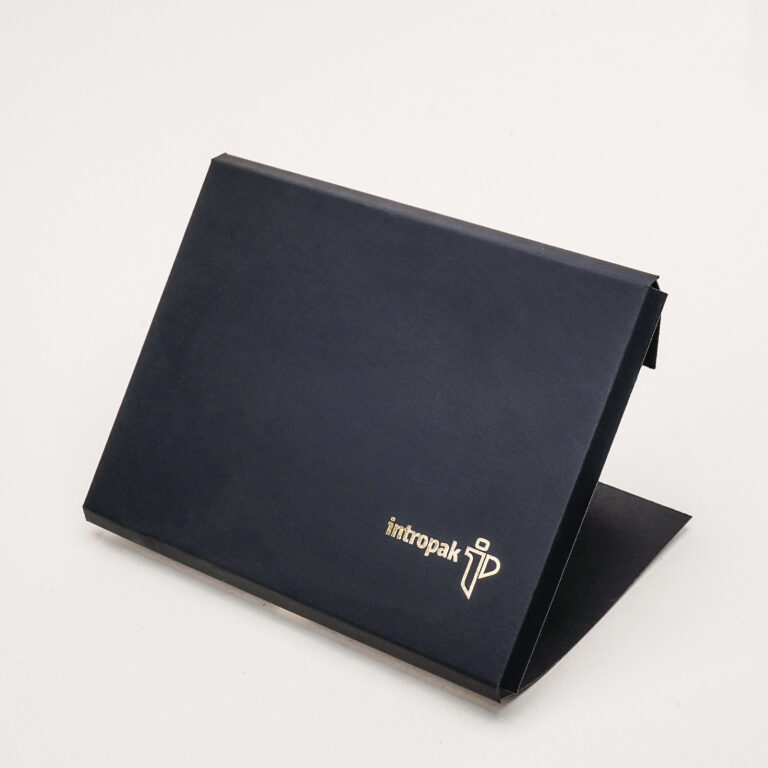

Gluing

We automatically glue one, three, and six-point as well as spatial packaging using cold and hot methods

FINISHING

Hot Stamping

Gold-plating of packaging, i.e. hot-stamping of coloured foil.

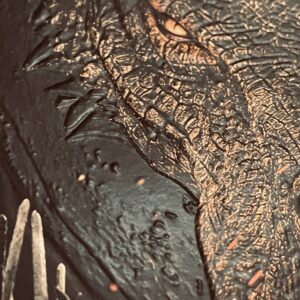

Embossing

Embossing of an item onto a surface. We carry out structural embossing and Braille embossing

Druk na metalizie

Drukujemy na papierze pokrytym folią metalizowaną

Hybrid varnishes

Application of a special varnish structure to the surface of the packaging.

UV selective varnish

Application of a glossy or matt effect.

Laminating

We protect sheets with glossy, matt, satin and anti-scratch film.

Usługi

Konfekcja

Pakujemy, przepakowujemy, składamy oraz kompletujemy gotowe produkty.

Oklejanie opakowań

Produkujemy ekskluzywne opakowania typu Rigid Box.

Wklejanie szybek

Wklejamy automatycznie plastikowe okienka. Szybka może być narożna oraz płaska.

Kaszerowanie

Automatycznie łączymy ze sobą dwa arkusze tektury litej.

Wklejanie tasiemek

Automatyczne wklejanie tasiemek oraz zrywek do kopert kurierskich.

Wklejanie tray

Automatyczna linia do wklejania tray – plastikowe tacki na płyty CD